Comparing Laser Engraving vs. Traditional Engraving Methods

Introduction to Engraving Techniques

Engraving has been a revered art form for centuries, used to immortalize designs, create intricate details, and personalize objects for both aesthetic and practical purposes. Today, the world of engraving is divided primarily between traditional methods and modern laser engraving. Each method has its own advantages and unique characteristics that cater to different needs and preferences.

Traditional engraving has a rich history, often associated with skilled artisans who meticulously carve designs by hand or with the aid of mechanical tools. On the other hand, laser engraving is a product of technological advancement, offering precision and speed that manual methods can't match. In this blog post, we'll explore the differences, benefits, and limitations of these two popular engraving methods.

Understanding Traditional Engraving

Traditional engraving methods include techniques such as hand engraving, rotary engraving, and acid etching. These methods rely on physical tools to cut into the material's surface, creating grooves and patterns. Hand engraving, for instance, uses a burin to carve intricate lines, while rotary engraving employs a spinning cutter for deeper cuts.

Advantages of Traditional Engraving

One of the key benefits of traditional engraving is its tactile quality. The depth and texture achieved through manual methods are often more pronounced, making it ideal for creating designs with a classic, artisanal feel. Additionally, traditional engraving can be performed on a wide variety of materials, including metals, glass, and wood.

Another advantage is the potential for personalization. Skilled artisans can engrave freehand designs that are truly unique, offering a level of artistic expression that is highly valued in custom projects.

The Rise of Laser Engraving

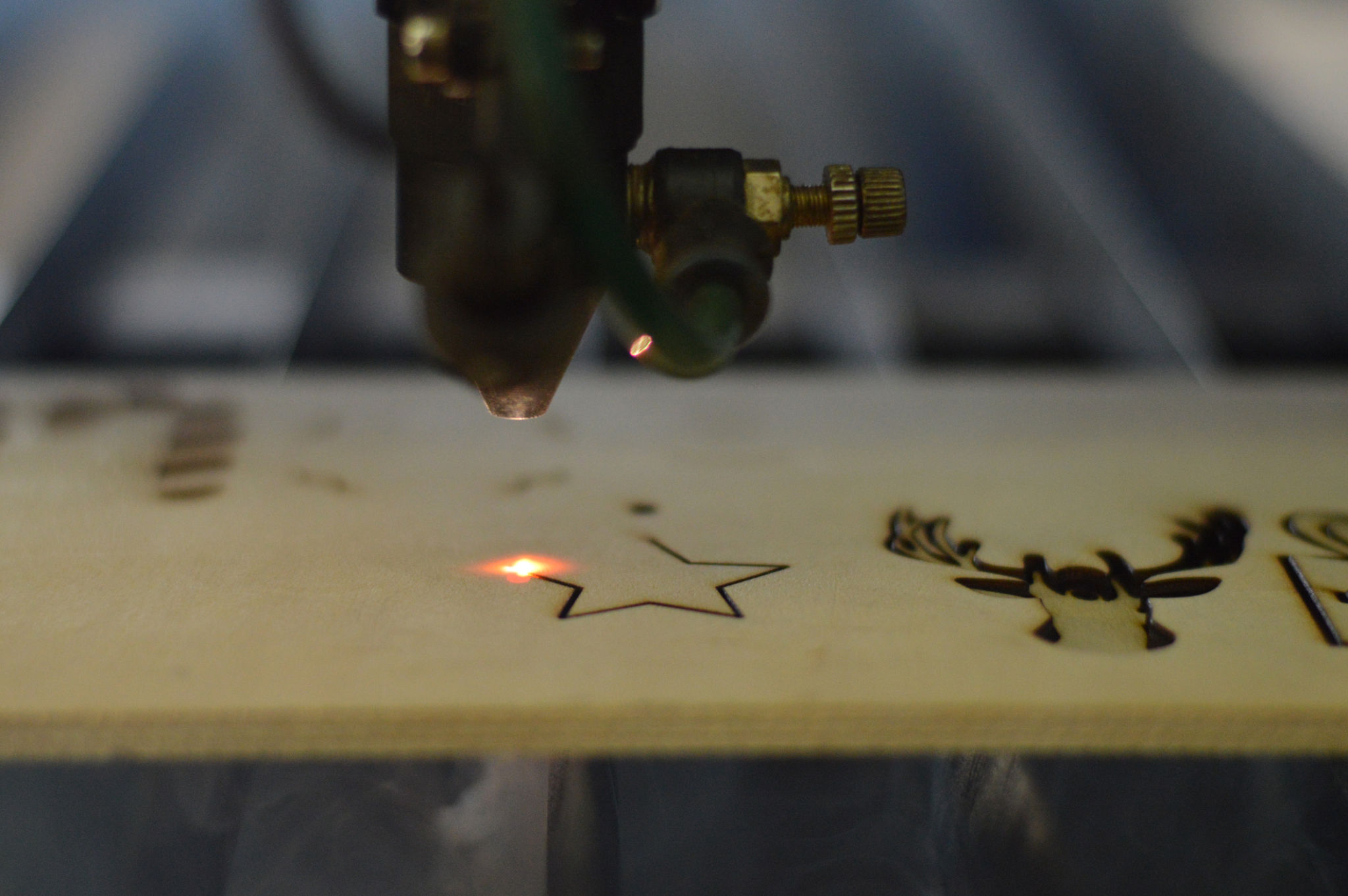

Laser engraving utilizes a focused beam of light to vaporize material and create precise designs on a wide range of surfaces. This method has gained popularity due to its speed, accuracy, and automation capabilities. Laser engravers can reproduce intricate designs with incredible detail and consistency, making it ideal for mass production.

Benefits of Laser Engraving

The most significant advantage of laser engraving is its precision. It can achieve fine details that are difficult to replicate with traditional tools. This precision makes laser engraving perfect for intricate designs, logos, and text on small items like jewelry or electronics.

Furthermore, laser engraving is highly efficient. It can quickly produce large quantities of engraved items with consistent quality, saving both time and labor costs. Additionally, it offers versatility in terms of materials, easily working with metals, plastics, glass, leather, and more.

Comparing Costs and Applications

When it comes to cost considerations, traditional engraving can be more expensive due to the labor-intensive nature of the work and the skill required from artisans. In contrast, laser engraving requires an initial investment in equipment but offers lower operational costs in the long run due to its automation.

In terms of applications, traditional engraving is often favored for custom and one-of-a-kind pieces where artistic value is paramount. Laser engraving is preferred for commercial purposes where uniformity and speed are essential—such as in branding or producing personalized promotional items.

Conclusion: Choosing the Right Method

The choice between laser and traditional engraving ultimately depends on your specific needs. If you value artistry and uniqueness, traditional engraving might be your preferred option. However, if precision, speed, and consistency are your priorities, laser engraving is likely the better choice.

Both methods have their place in today's market, catering to different demands and delivering outstanding results when used appropriately. By understanding the strengths of each technique, you can make an informed decision that best suits your project requirements.